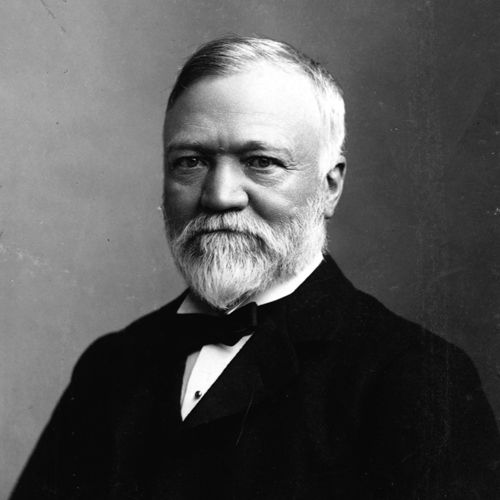

The steel Carnegie used made skyscrapers and railroads affordable, fueling the burgeoning industrial economy. But his drive for efficiency eroded worker safety and drove many to strike. Eventually, his steel empire attracted the attention of banker JP Morgan, who bought Carnegie Steel and formed U.S. Steel, the world’s first billion dollar corporation.

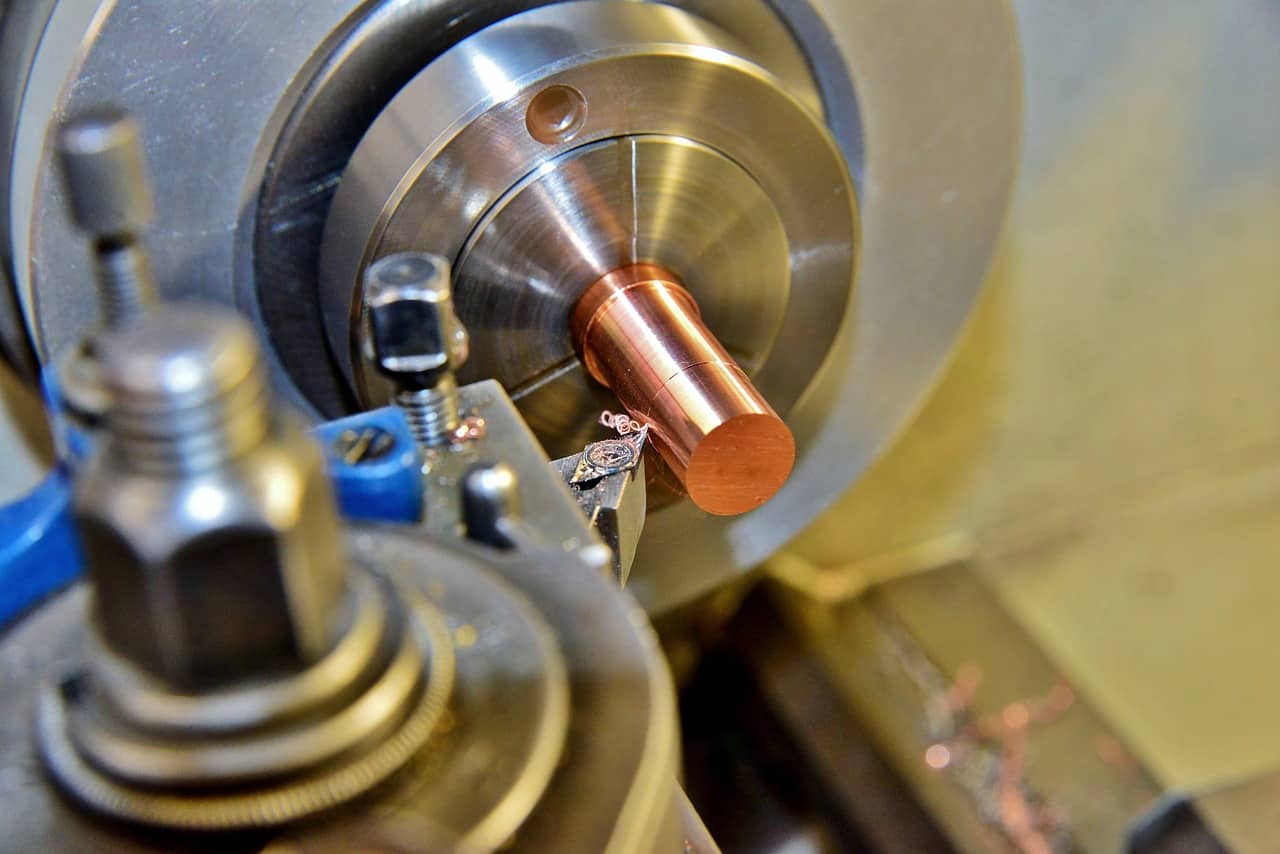

Implementation of the Bessemer Process

During his lifetime, Carnegie’s technical and business innovations transformed steel production in America. The girders and railway tracks that he produced allowed the United States to rapidly transform from an agrarian to an industrial society.

The steel he produced was affordable and in abundant supply, enabling railroads to be built across the country and skyscrapers to rise to the skies. This helped fuel America’s economic boom and he became one of the richest men in the world.

He was also a master of business, employing a strategy known as vertical and horizontal integration to maximize profits. He kept a substantial portion of his profits to ensure profitability in bad times and used the rest for business expansion. He favored constant technological and business innovation to reduce operating costs, which had much greater impact on profit than construction costs.

Bessemer’s process was revolutionary because it allowed for a higher-quality steel to be made at a much faster rate. His furnaces pushed air through molten iron, which caused it to decarbonize and resulted in a stronger and more pure form of steel.

This process was not without its share of problems, however. It was extremely dangerous and workers were often subject to horrific injuries. It also required a large amount of capital to invest in the equipment necessary for the operation.

Use of the Open Hearth Furnace System

While the Bessemer process ushered in a new era of steelmaking, Carnegie still relied heavily on the open hearth furnace system. This allowed him to make steel with a combination of liquid pig iron from the blast furnace and steel scrap. The result was a much lower production cost.

The open hearth furnace was also a safer way to produce steel, allowing workers to work more comfortably in the mill. This was a significant improvement over the dangerous conditions of earlier steel plants. Despite these improvements, there were still flames and noise, and the use of protective equipment was limited.

Carnegie also consolidated all of his plants into the Carnegie Steel Company, which helped him to increase efficiency. He also invested in the best technology, even if it meant ripping out old equipment and replacing it with newer technology. He knew that the long-term savings would outweigh the short-term costs, and his mills were among the most productive in the world.

Nevertheless, there were still conflicts between employees and management. In 1892, workers at the Homestead plant went on strike and clashed with private security agents in a bloody battle that ultimately ended in victory for the company. Eventually, Carnegie sold his empire on a scribbled note to J.P. Morgan, who merged it into U.S Steel.

Implementation of Overhead Cranes and Hoists

When Andrew Carnegie emigrated with his family from Scotland to America in 1848, steel was expensive to make and his new home’s railroad industry had an enormous appetite. Carnegie made a small fortune as a telegraph operator for the Pennsylvania Railroad and a Wall Street broker selling railroad bonds, but he was convinced that he could build something rather than just buy or sell it. That something would be steel.

The breakthrough came when British inventor Henry Bessemer showed Carnegie a process that allowed steel to be manufactured more quickly and efficiently from iron. Carnegie adopted the technology, and it revolutionized steel production in his mills.

A crucial aspect of the process was enabling the continuous flow of molten iron, which required huge amounts of energy. The answer was a huge steam powered machine called the blast furnace. This machine blew air through the molten iron, burning off carbon and creating steel. It dramatically reduced production time and energy costs.

In addition to utilizing the Bessemer process, Carnegie embraced vertical integration, purchasing mines for raw materials and acquiring rail lines for efficient transportation of his products. This strategy maximized profits and minimized inefficiencies by controlling all stages of production and distribution under one company umbrella.

This business philosophy was a key factor in Carnegie’s meteoric rise to steel power. During his lifetime, Carnegie’s steel companies helped the nation expand railways and skyscrapers. America’s urban population grew 87 times from 1860 to 1900, due in large part to the steel built by Carnegie.

Implementation of the Steel Mixer

In a time when steel was expensive, Carnegie’s invention allowed it to be mass produced, and that led to a major expansion of American industry. However, this could not have happened without his many other innovations.

One of his most significant breakthroughs was implementing the steel mixer, which enabled him to take low-utility scrap metal (such as old wrought iron rails) and turn it into high-value products such as armor plate and boiler plate for locomotives. This was a revolutionary process, and it made him a very wealthy man.

He used his money wisely, retaining a portion of profits in good times to ensure he would be able to continue production during lean times, and to buy out competitors and absorb them into his own company (in a strategy called vertical integration). And he was always open to business innovation that could reduce operating costs even by just a little.

Carnegie was a hard-working and ruthless businessman, which helped him achieve so much success. But his shrewdness and aggressiveness also landed him in some trouble, most notably in the Homestead Strike of 1892. He was unable to maintain his monopoly on the steel industry, and in 1901 Carnegie Steel was merged into J.P. Morgan’s new company – United States Steel Corporation – which dominated the American steel market for decades.