METAL PROCESSING EXPERTS

Metal Stamping

Metal stamping is a manufacturing process used to create metal parts using precision tooling and presses. From simple brackets to intricate components, metal stamping offers a cost-effective and efficient solution for producing high-quality parts with consistent accuracy.

OUR APPROACH TO METAL STAMPING

Welcome to Huada, a leading provider of high-quality metal stamping services. With years of experience in the industry, we specialize in delivering precise and cost-effective solutions for wide range of industries, including roofing, medical, lighting, piping, drainage, gardening, automotive, energy and kitchen. From initial design consultation to final production, we work closely with you every step of the way to ensure optimal outcomes and complete satisfaction.

OUR METAL STAMPING CAPABILITIES

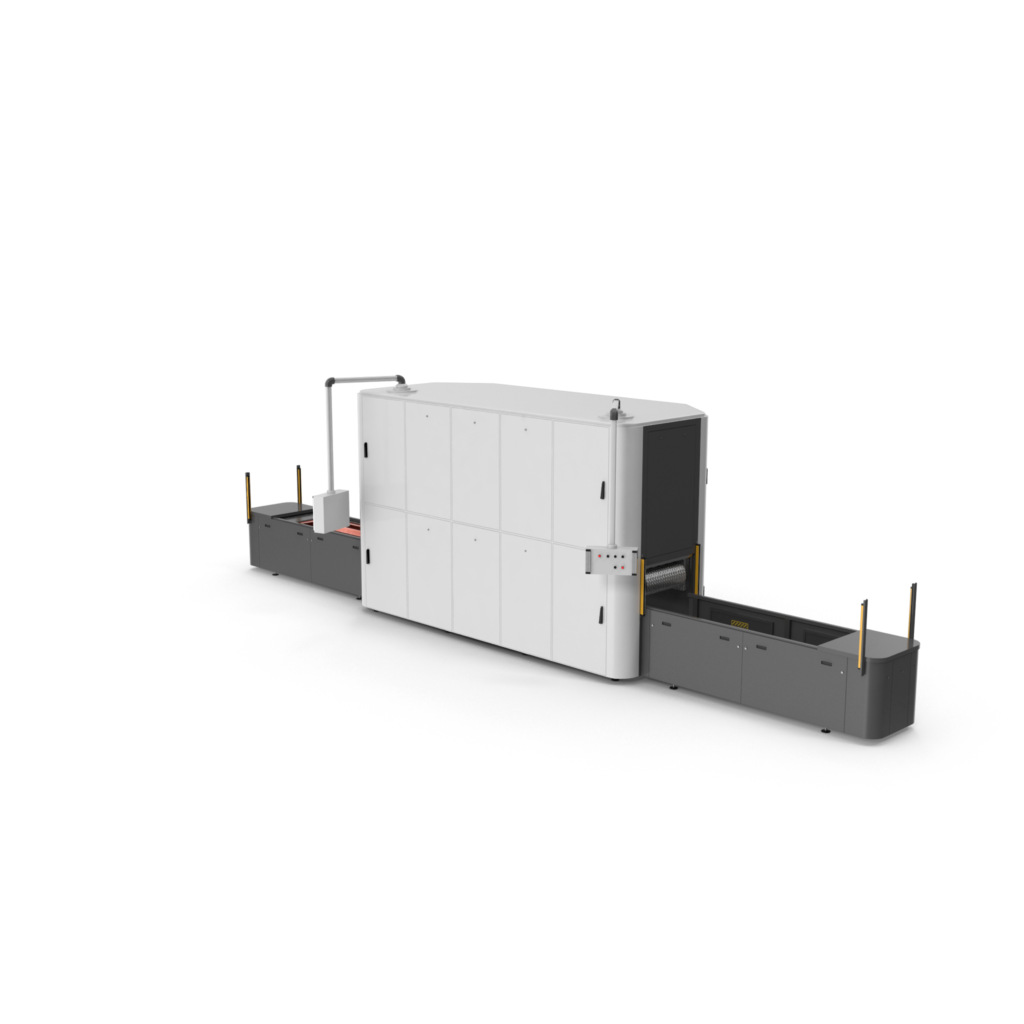

- Advance equipment: Our state-of-the-art facility is equipped with the latest metal stamping machinery, allowing us to handle wide range of materials and complexities.

- Diverse techniques: From progressive die stamping to deep drawing, we offer a comprehensive suite of metal stamping techniques to suit various applications.

- Quality assurance: With stringent quality control measures in place, we ensure that every stamped component meets the highest standards precision and performance.

KEY BENEFITS OF METAL STAMPING:

- Precision: Metal stamping allows to produce parts with tight tolerances and complex geometries, ensuring precise fit and function.

- Efficiency: With the ability to produce parts at high speeds and volumes, metal stamping offers unparalleled efficiency, making it ideal for both prototyping and mass production.

- Cost-Effectiveness: By minimizing material waste and reducing secondary operations, metal stamping helps lower production costs while maintaining exceptional quality.

- Versatility: From automotive and aerospace to electronics and consumer goods, metal stamping serves a wide range of industries, catering to diverse application needs.

- Consistency: With advanced tooling and quality control measures, metal stamping delivers consistent results batch after batch, ensuring reliability and performance.

Metal stamping is a manufacturing process where flat metal sheets are transformed into intricate shapes through the use of specialized dies and presses. It is an efficient method for producing high volumes of consistent and precise metal parts.

Absolutely! At Huada, we understand that each project is unique. Our team of skilled engineers and designers will work closely with you to turn your concept into reality. From simple to complex designs, we have the expertise to bring your vision to life.

We work with a variety of materials including stainless steel, aluminum, brass, copper, and more. Our extensive material selection ensures that we can meet your specific requirements for strength, corrosion resistance, and aesthetic appeal.

Quality is our top priority. We follow strict quality control processes throughout every step of the production process. From material inspection to final product testing, we ensure that each metal part meets the highest standards of quality and performance.

With state-of-the-art facilities and a team of experienced professionals, Huada has the capacity to handle both small and large-scale production. Whether you need a single prototype or a high-volume production run, we have the capability to deliver on time and within budget.

Tool and Die Design

Huada offers comprehensive tool and die design services to ensure the efficient and precise fabrication of metal stamping components. Our skilled design engineers work closely with clients to create customized tooling solutions tailored to their specific requirements. By optimizing die designs, we enhance the overall efficiency and accuracy of the metal stamping process, resulting in high-quality components.

Prototyping and Testing

Huada provides prototyping and testing services that enable clients to validate their designs before full-scale production. Through rapid prototyping techniques, we can quickly produce sample metal stamping components for evaluation and testing. This iterative process allows for design refinements and ensures that the final production runs are accurate and meet the desired specifications.

Secondary Operations and Finishing

In addition to metal stamping, Huada offers a range of secondary operations and finishing services. This includes processes such as deburring, trimming, welding, surface treatment, and coating. These operations add value to the metal stamping components by improving their functionality, appearance, and durability. Huada’s expertise in secondary operations ensures that the final products are ready for assembly or direct use by the clients.

Contact Huada Now

Ready to turn your metal fantasies into reality? Reach out to us through the contact form below, and let’s embark on a journey of craftsmanship together.