The open hearth process (also known as the Siemens-Martin process) was a steelmaking technique that until recently accounted for the major portion of all steel produced. It offered advantages in raw material selection, precise composition control and efficient impurity removal.

The open hearth furnace used in this method is lined with refractory materials and gas or coal fires heat it. Air is blown through the steel mass to cause oxidation, removing carbon, Sulphur and Phosphorous.

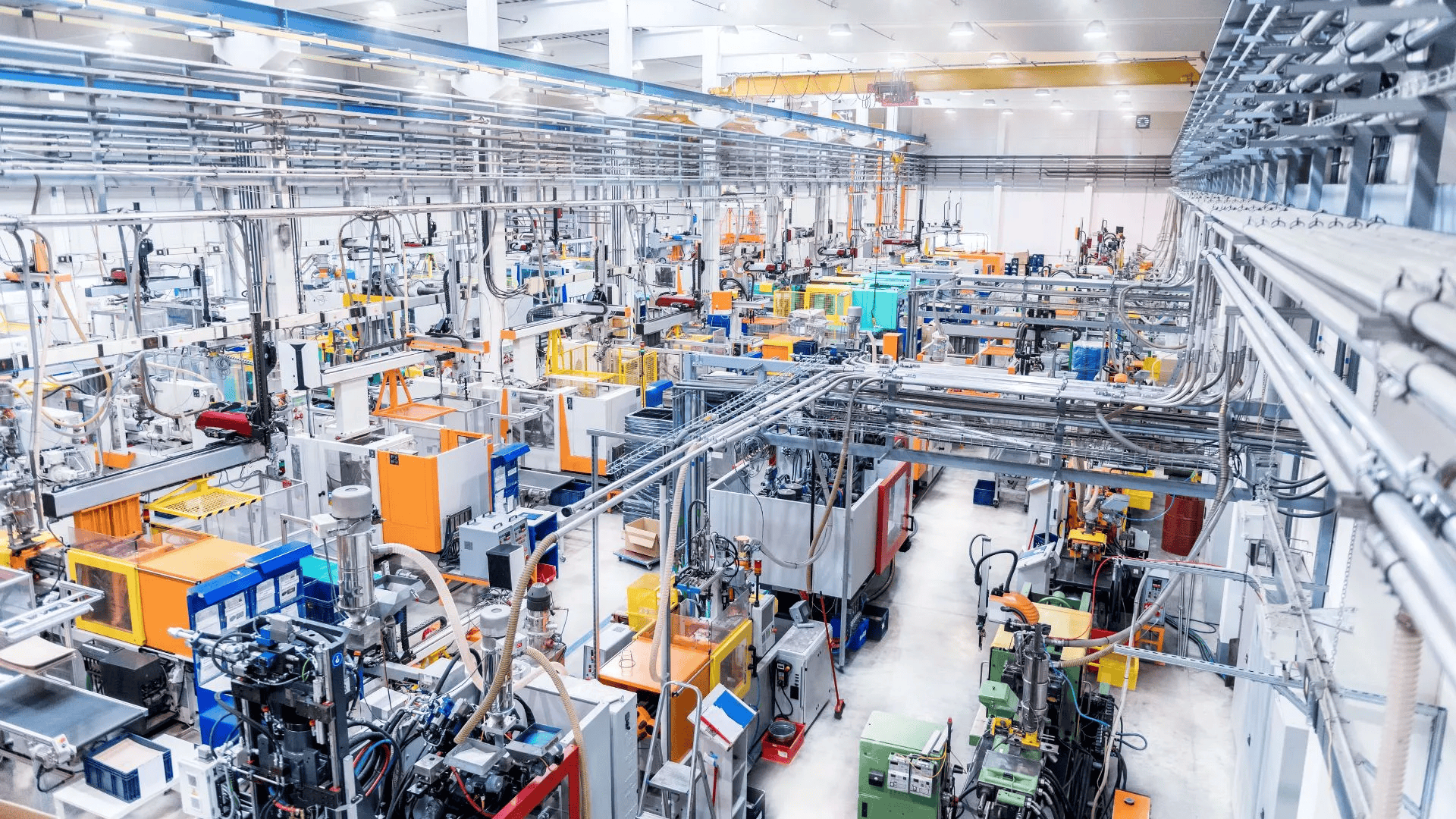

Raw Materials

Iron ore, coal and limestone are the main raw materials used in steel manufacturing. They are melted together in blast furnaces to produce molten iron or hot metal, which still contains impurities like carbon and sulphides. The carbon is removed by reducing the temperature of the iron mass with coal (bituminous coal). This produces porous lumps called coke that are used as a fuel and to add more heat to the furnace, thus lowering its melting point.

Other impurities are removed by oxidation with air blowing through the molten iron or by using basic or acid open hearth steel processes or by electric arc and basic oxygen methods. In the latter a molten charge of pig iron and steel scrap with alloying elements is contained in a converter and a jet of high purity gaseous oxygen is directed over it.

Other additives are also incorporated in the steel to give it specific properties such as toughness, strength and wear resistance. These include chromium, nickel, molybdenum and vanadium in the form of ferrous alloys. The steel is poured into ingot moulds to cool and solidify.

Melting

The raw materials are melted together in a blast furnace to form molten iron. The molten metal is then cast into ingot moulds and allowed to cool before being tapped into large ladles, usually with a crane. Various types of ladles are used, including bottom-pour, lip-pour, teapot, bull, and trolley. The ladles are preheated to ensure they maintain a pouring temperature when the steel is poured into them.

The Siemens-Martin process is the major method by which steel is made today, and it accounts for about three-quarters of all production. It uses a wider range of raw materials than the Bessemer process and is adaptable to economic conditions.

The molten steel is then refined in a basic oxygen furnace (BOS) or an electric arc furnace (EAF). A jet of high purity gaseous oxygen is directed through the liquid steel to burn off impurities and reduce the carbon content to low levels. Other unit processes may include deoxidation, desulfurization, degassing, and alloying. These unit processes vary depending on the type of steel being produced. The resulting steel is known as secondary steel.

Refining

The open hearth process has now been superseded by the basic oxygen and electric arc processes, but it still accounts for one-sixth of all steel made in the world. The Siemens-Martin process is especially well suited to the use of ores that contain high concentrations of phosphorous and sulfur.

It is also more flexible in raw material selection, and can be used with a mixture of pig iron and scrap steel. This allows it to adapt to varying industrial demands over longer periods of time than the Bessemer converter.

In addition to deoxidation, the Siemens-Martin process also performs several other unit processes to improve the quality of steel. These include degassing (removal of hydrogen and nitrogen), and alloying or decarburization to a low carbon content, usually below 1 percent. This is done by blowing air through the molten metal in order to raise its temperature and promote a reaction that reduces the carbon content. This also improves mixing and purges the iron of contaminating oxides. The process is also capable of reducing the phosphorous and sulfur content of the steel.

Alloying

Steel is made up mainly of iron and carbon but alloying with elements like nickel, manganese and molybdenum can improve specific properties, giving rise to a wide range of different steel alloys that can be tailored for various applications. These alloys are essential to the infrastructural development and technological advancements of modern society.

Alloying is accomplished by melting the base alloys in an electric furnace for 8 to 12 hours. Once the molten metal has cooled to below 1,600 degrees Fahrenheit, it is annealed to alter its chemical composition and remove impurities such as mill scale.

The alloy is then cast for rolling or forging into its final shape. High-performance alloys are often subjected to up to 40 distinct cycles of hot and cold working, annealing, pickling and remelting before they achieve their required dimensions.

In the early days of the open hearth process, the slag was raked out to produce a second more basic slag that could be used to catch sulphur and phosphorous impurities. Then additions of ferromanganese and ferro silicon were made to bring the level of carbon down to the required figure.

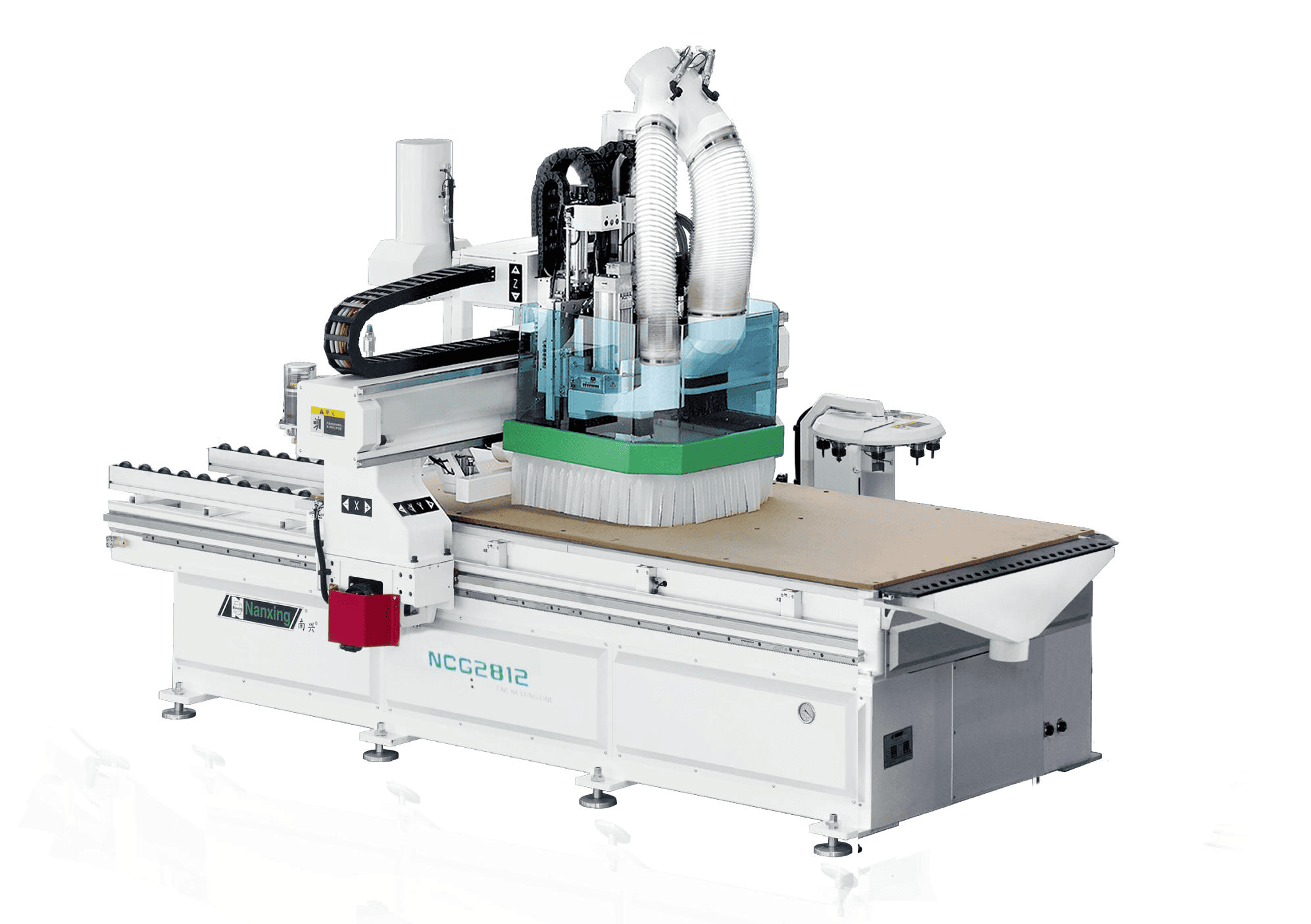

Casting

Using the open hearth process, alloying elements are introduced into the steel to achieve specific properties. This was a widely used method throughout the 20th century and still accounts for a significant percentage of global steel production.

This technique is an improvement on the Bessemer process, which involves blowing air through molten iron in a continuous furnace. It allows a greater variety of raw materials and precise adjustments in composition, allowing the manufacture of diverse steel grades with unique properties. It also significantly reduces impurity content through slag formation.

The process uses a regenerative fired furnace, which is lined with basic or acid material (depending on the process) and a charge of either scrap iron haematite or pig iron is melted in it. As the metal is molten, air is blown through it to remove impurities and increase the temperature.

When the impurities are reduced to the required level, the liquid steel is tapped into large ladles and poured into ingot moulds. The slag left behind in the ladle is known as the sprue.