Image Source: Pixabay

Cutting circles out of sheet metal may appear daunting, but it can actually be done quite easily using the appropriate tools and techniques for an accurate cut.

Start by marking your desired circle using a compass or circle-cutting jig. Next, use a hole saw or jigsaw fitted with metal-cutting blade to trace and cut along your marked line.

Marking the Circle

Cutting circles out of sheet metal may seem intimidating, but with the appropriate tools and techniques it can be accomplished quickly and effortlessly. To start off, mark your desired size of circle on the metal using either a compass or circle-cutting jig and ensure it is clear and visible before using a screwdriver to punch a hole at its centre before wedge your tin snips through that hole to follow your mark and cut.

If you prefer more precise methods of cutting sheet metal, use a hole saw. These hollow cylindrical bits attach easily to a drill or drill press and feature fine teeth designed to cut various materials such as sheet metal. As an alternative option, jigsaws with metal cutting blades may work but this method requires more effort as you must constantly keep in contact with the material while keeping the blade close by keeping pressure against its material surface.

Another option for creating holes in metal pieces is a hole punch, which features a pin at its jaws that punctures metal when force is applied to its jaws. You could also try regular pliers but this could create uneven or jagged edges in your hole. No matter which tool you select, be sure to follow your circle mark carefully and make smooth cuts for best results and to prevent warping.

Drilling the Hole

When cutting sheet metal into circular pieces that require holes to be cut out, using a drill and cutter tool is the most ideal approach. A cutter is a circular bit with hollow cylinder shape and fine teeth for cutting through various materials; alternatively you could also try using a jigsaw with metal cutting blade as another alternative; although that method would take more time and may result in poorer cuts.

If the material is thin enough, you could use a forstner bit or hole saw to trim away excess material. Unfortunately, this method is often impractical for most cases and rotary table milling machines provide a much more precise method that takes less effort to use and achieve accurate results more quickly and easily.

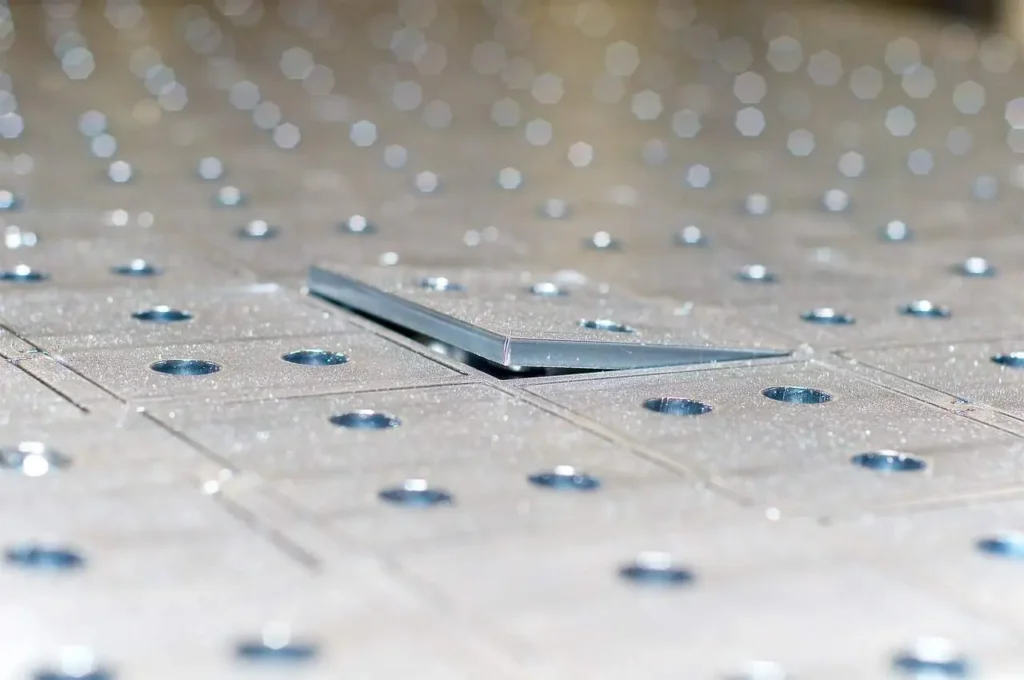

Before using the rotary table, first make sure that your piece of metal is secured to the workbench using clamps or double-stick tape. Attach the rotary table to your pillar drill using its appropriate chuck and lock it securely before setting its diameter accordingly and starting cutting. Please ensure all safety glasses, Kevlar gloves, and PPE are worn before proceeding with this task.

Cutting the Circle

Once the hole has been drilled and its edges cleaned up, it’s time to cut a circle using appropriate tools and techniques. This should be an effortless process.

For smaller circles, a hole saw with a metal-cutting blade is often the optimal solution. This type of cutting tool is commonly found in woodshops and can easily cut through various forms of metal including thin sheet metal. For larger circles, however, a jigsaw with metal-cutting blade or circular saw may be required.

When cutting circles, it is essential to follow the marked lines closely and create clean cuts with smooth, even strokes. Checking progress periodically and making necessary changes as needed are also useful tactics for cutting metal-cutting tools safely and ensuring maximum results. Finally, gloves and eye protection must always be worn when operating these tools.

Once the circle has been cut, using deburring tools or sandpaper is recommended to smooth away any rough or jagged edges and create a polished and professional appearance for the finished product. In addition, cleaning the surrounding area of metal to remove dust or debris should also be performed for best results. Following these tips can quickly and efficiently cut a perfect circle in sheet metal – an invaluable skill that could prove essential when undertaking metalworking projects!

Image Source: Pixabay

Finishing the Edges

Cutting, lasering or punching sheet metal produces sharp edges that must be smoothed for aesthetic and functional reasons. Customers increasingly demand burr-free products and defined rounded edges both outside and within their housings.

Various tools may be suitable based on the size and thickness of your circle. A jigsaw equipped with a metal cutting blade works well when creating smaller circles; larger circles usually call for hole sawing or even an automated circular shear which cuts sheet metal coils as they unwound.

When cutting circles from sheet metal, the most essential aspect is to use your tool correctly and practice on scrap pieces of sheet metal before starting on any major projects. Our experts in CNC machining and sheet metal fabrication would be more than happy to provide assistance and quote our services accordingly.