If a company lacks the internal bandwidth to handle product production, contract manufacturing is an option. This allows the business to focus on marketing and sales while contracting out the creation of products.

Intellectual property loss is a risk that comes with the decision to use a contract manufacturer. Since the recent increase in intellectual property theft, government and corporate leaders are fighting to improve security.

1. Cost

Companies may not have the capital to invest in an entire production process at the outset of a project. This is where contract manufacturing comes in: the manufacturer is able to offer the services of their facilities and equipment at a fraction of the cost of doing it in-house.

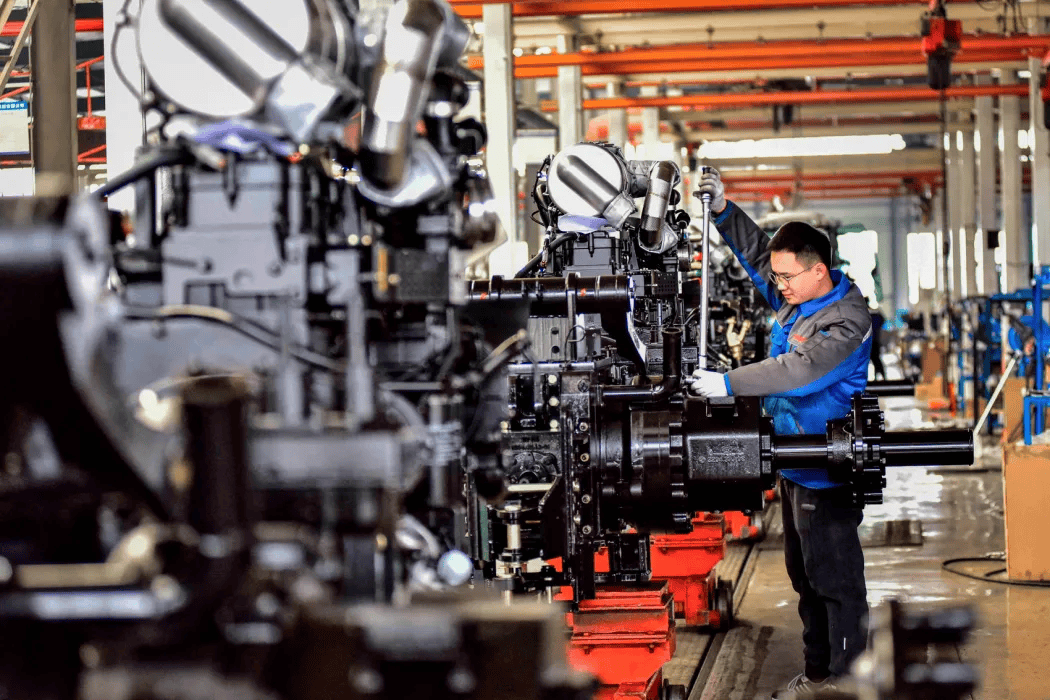

Contract manufacturers typically have a highly-specialized workforce in place. This allows for greater efficiency as they are able to quickly shift human resources from one project to another. This, in turn, can reduce labor costs per unit of production.

The cost of contract manufacturing can vary greatly depending on the complexity and size of the product being developed. It can also be affected by the location of the contract manufacturer, as different regions and countries have differing labor costs and tax structures. It’s important to research contract manufacturers and reach out for quotes to ensure that you are getting an accurate picture of the cost of your production run. It’s also worth noting that contract manufacturers will add their overhead and profit margin to the final unit price.

2. Time

In addition to cost benefits, contract manufacturing saves companies time by allowing them to focus on other aspects of their business. This allows them to create new product lines, improve existing products or invest in research and development.

However, companies need to carefully evaluate just how long they can rely on contract manufacturers before internalizing production. In some cases, this isn’t an option, such as when a company has spent heavily on developing a formula that it holds patents for. Giving it away to a contract manufacturer will ultimately be very costly in the long run, especially if it results in a competitor using the formula and reaping profits.

Another consideration is that contract manufacturers have their own production process and timelines. It may take some time for them to complete the job based on the company’s needs, depending on their workload and capacity. This can be a big hurdle for some leaders to overcome and requires them to let go of control. However, if a company can find the right partner to suit its requirements, it will reduce time-to-market and improve its profitability.

3. Quality

Having an amazing new product idea is great, but actually getting that product into production can be a huge challenge. The cost of labor, raw materials, and manufacturing facilities can drain even the most financially sound companies.

Contract manufacturing can be a solution for companies with limited resources or those who aren’t ready to invest in the costs of an in-house production line. By working with an established and respected contract manufacturer, your company can save on labour costs while reducing risk of quality loss.

A good contract manufacturer will provide you with a detailed contract proposal and cost estimate at the beginning of your relationship with them. They should also be willing to show you around their workshop and explain the manufacturing processes, tools, and materials they’ll use to create your dream product.

It’s also important to ensure that the contract manufacturer you choose is a trustworthy and reliable partner. A less-than-ethical contract manufacturer may be tempted to cut corners and reduce costs, which could negatively impact your product’s quality or your business reputation.

4. Flexibility

Contract manufacturers have many facilities and can easily shift production to meet demand. They are used to changing batch sizes, adjusting lead times, and maintaining quality standards. This flexibility can help companies get their products to market much faster than they could with in-house production.

However, if a contract manufacturer is not equipped to handle rapid growth, it can cause problems. Contract manufacturing can be a great way to save money, but it’s important to select a supplier that is reliable and able to work well under pressure.

Another downside is that contract manufacturing can take away some control from a company. Some leaders find it hard to give up this power and trust a third party to make decisions on their behalf. It’s also important to choose a contract manufacturer with plenty of capacity so that they can quickly scale up or down during peak or seasonal production. They should also be able to provide a detailed list of services and the steps they will take to create a product from scratch. This will prevent misunderstandings and reduce risk.

5. Innovation

Depending on the industry, contract manufacturing can encompass everything from producing components to complete start-to-finish manufacturing. The specifics are outlined in the contract between the company doing the manufacturing and the company being contracted.

Having contract manufacturing available to companies can be very helpful when they need to test a new product line or are looking for ways to improve their existing products. This allows them to save money by not having to invest in their own production equipment and hiring employees.

Contract manufacturers also often have a wealth of technical expertise that they can share with their clients. This can help them solve problems and get their products to market more quickly. They may be able to recommend different materials, design features, or other improvements that could reduce cost or increase quality. In addition, contract manufacturers may have established procedures for inspecting products and replacing defective ones. This is a huge savings for companies who can avoid customer service expenses and damage to their reputation by catching issues early. These advantages make contract manufacturing a viable option for businesses of all sizes.