The global metal fabrication market is poised for significant growth, driven by a myriad of factors that are shaping the industry landscape. According to recent projections, the market size is expected to reach an impressive $29.63 billion by the year 2030. With a compound annual growth rate (CAGR) of 4.7%, the period leading up to 2030 is forecasted as one of substantial development and opportunity within this sector.

Understanding Metal Fabrication

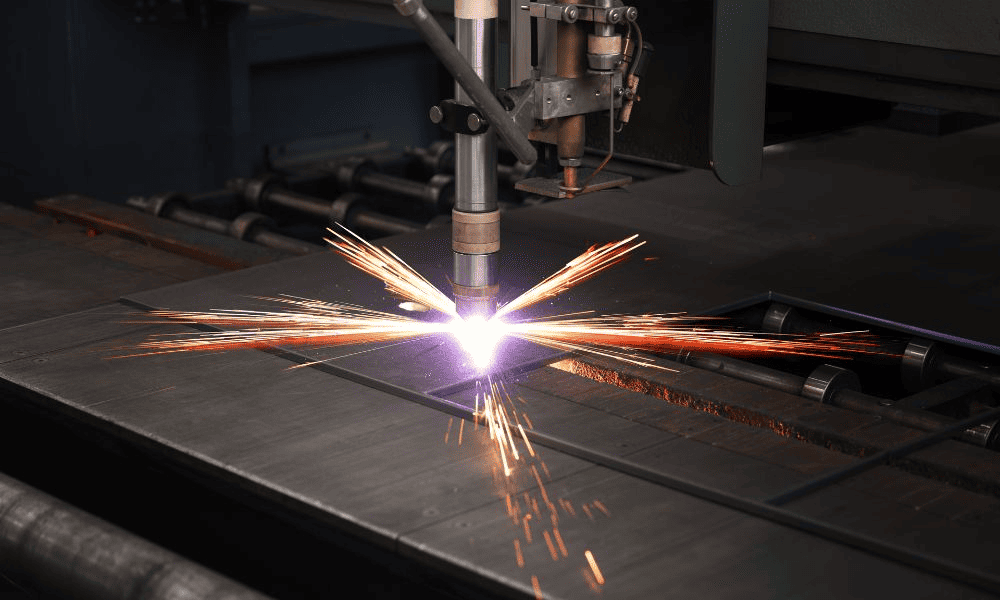

Metal fabrication is a critical industry involving the creation of metal structures and components through processes such as cutting, bending, and assembling. The industry serves a broad spectrum of sectors, including automotive, aerospace, construction, and electronics. By transforming raw metal materials into finished products, metal fabrication is indispensable to modern manufacturing and construction projects.

Key Drivers of Growth

The forecast for robust market expansion is influenced by several key drivers:

Technological Advancements

- Automation and Robotics: The adoption of advanced technologies like automation and robotics has revolutionized the metal fabrication industry. These technologies enhance precision, efficiency, and scalability, making them essential for meeting growing demand.

- 3D Printing: The integration of 3D printing in metal fabrication opens up new possibilities for complex design and customization, driving innovation and reducing production costs.

Surging Demand Across Sectors

- Automotive Industry: The ongoing development of electric vehicles (EVs) has boosted the demand for metal components, driving growth within the sector.

- Construction Industry: With urbanization and infrastructure projects on the rise globally, the need for fabricated metal products like beams and panels is escalating.

Emerging Economies

Emerging economies, particularly in Asia-Pacific and Latin America, are experiencing rapid industrialization, which is fueling a demand surge for metal fabrication services. Economic growth in these regions is creating vast opportunities for market expansion and attracting investments from prominent players.

Challenges in the Metal Fabrication Market

While the outlook is positive, the metal fabrication industry faces certain challenges that could impact growth:

Raw Material Price Fluctuations

Volatility in the prices of raw materials, such as steel and aluminum, poses a significant challenge. Price fluctuations can impact profitability and pricing strategies for manufacturers, necessitating efficient supply chain and inventory management.

Environmental Regulations

Increasingly stringent environmental regulations require metal fabricators to adopt sustainable practices. This includes minimizing waste, reducing emissions, and enhancing energy efficiency. Compliance with these regulations may require significant investment in cleaner technologies and processes.

Skilled Workforce Shortage

The industry is grappling with a shortage of skilled labor, a trend that could hamper production capabilities. Addressing the skills gap by investing in training and upskilling programs is imperative for maintaining competitive edge.

Future Opportunities

Despite challenges, the future of the metal fabrication market shines bright, offering numerous opportunities for growth and innovation:

Adoption of Smart Manufacturing

- Industry 4.0: The convergence of digital technologies in manufacturing, known as Industry 4.0, is transforming operations. Smart manufacturing processes utilizing the Internet of Things (IoT), big data analytics, and artificial intelligence (AI) are set to redefine the metal fabrication landscape.

Focus on Sustainability

- Green Fabrication Practices: The push toward sustainability is driving the adoption of eco-friendly fabrication methods. Companies focusing on reducing environmental impact, investing in renewable energy sources, and promoting recycling are gaining preference among consumers and partners.

Customization and Diversification

As customer demands grow increasingly specific, metal fabricators that offer customization and diversification services are well-positioned for success. Tailored solutions enable manufacturers to cater to niche markets and gain a competitive advantage.

Conclusion

The metal fabrication industry is on an upward trajectory, projected to grow substantially over the next decade. Companies that embrace technological innovation, navigate challenges effectively, and focus on sustainable practices will unlock significant opportunities. As the industry evolves, remaining agile and responsive to market dynamics will be key for capitalizing on the promising forecast for market expansion to $29.63 billion by 2030.