The global

metal stamping market is poised for significant growth over the next decade, driven by key industry dynamics and emerging trends. As manufacturers and consumers increasingly demand high-quality and durable metal components, the market is undergoing a transformation that promises both challenges and opportunities. This article will explore the major trends shaping the metal stamping industry and provide a comprehensive growth forecast from 2025 to 2032.

Understanding Metal Stamping

Metal stamping is a versatile and cost-effective process that involves the transformation of flat metal sheets into specific shapes through various techniques such as bending, punching, and embossing. This process is crucial in creating components for a range of sectors including automotive, aerospace, electronics, and household appliances.

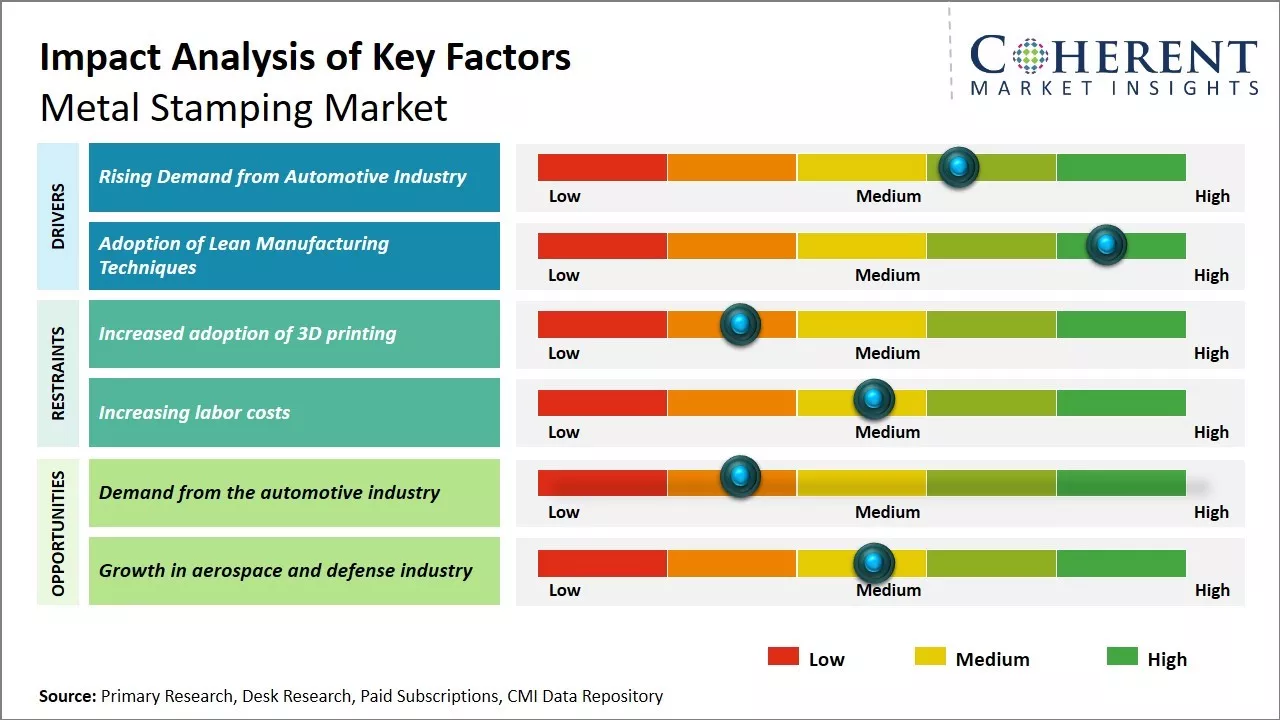

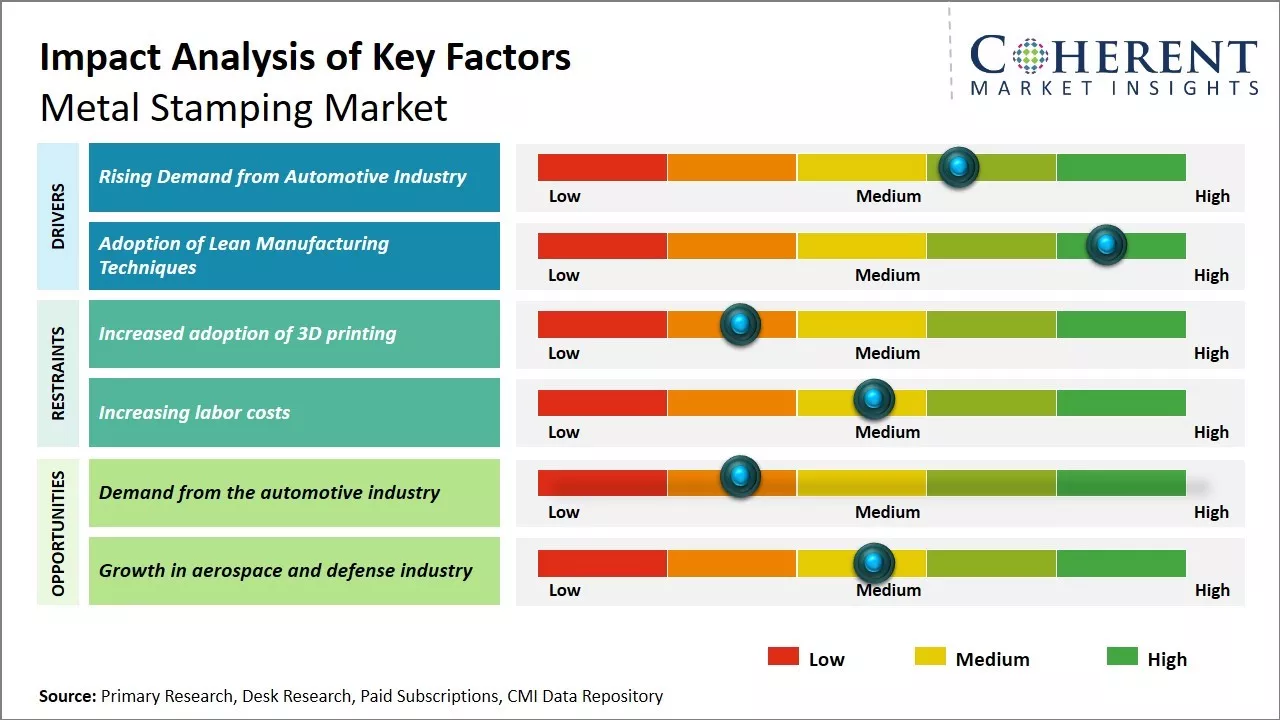

Key Growth Drivers

The increasing demand for metal stamping is driven by several factors:

- Automotive Industry Expansion: The demand for lightweight and high-performance automotive parts is fueling growth in the metal stamping market. As manufacturers strive to enhance fuel efficiency and reduce vehicle weight, metal stamped components are becoming essential.

- Technological Advancements: Innovations in stamping technologies, such as the integration of automation and robotics, are improving efficiency and precision, thus propelling market growth.

- Rising Consumer Electronics Production: With the constant evolution of consumer electronics, the demand for intricate and complex metal components is on the rise, encouraging advancements in stamping techniques.

- Construction Sector Growth: Increased urbanization and infrastructure development across the globe are leading to a higher demand for metal stamped products in the construction sector.

Emerging Trends Shaping the Market

To stay competitive in the rapidly evolving metal stamping market, it is critical to stay abreast of emerging trends:

1. Eco-Friendly Manufacturing Practices

The global push for sustainable manufacturing processes is leading to a shift towards environmentally friendly metal stamping techniques. Companies are investing in technologies that minimize waste and reduce the carbon footprint of production.

2. Integration of IoT and Smart Manufacturing

The integration of the Internet of Things (IoT) into manufacturing processes has revolutionized metal stamping operations. Smart manufacturing practices facilitate real-time monitoring and predictive maintenance, resulting in enhanced efficiency and reduced downtime.

3. Increased Use of Advanced Materials

There is a growing trend towards the use of advanced materials such as high-strength steel and aluminum alloys in metal stamping to meet the demands of lightweight and durable components. This trend is especially significant in the automotive and aerospace industries.

Challenges in the Metal Stamping Market

Despite the promising growth prospects, the metal stamping market faces several challenges:

- Fluctuating Raw Material Prices: The volatility in raw material prices can have a significant impact on production costs and profit margins.

- Skilled Labor Shortages: As the industry becomes more technologically advanced, there is a growing need for skilled workers capable of operating sophisticated machinery and systems.

- Stringent Regulations: Compliance with environmental and safety regulations can be costly and resource-intensive, posing a challenge for manufacturers.

Market Forecast 2025-2032

The metal stamping market is expected to witness robust growth in the coming years, with projections indicating a compound annual growth rate (CAGR) of 4.1% from 2025 to 2032. This growth will be primarily driven by:

- Rising Demand in Emerging Economies: Rapid industrialization and economic growth in emerging markets such as Asia-Pacific and Latin America are expected to boost demand for metal stamped products.

- Increased Investment in R&D: Continued investment in research and development will drive innovation and open new avenues for growth in the metal stamping sector.

- Partnerships and Collaborations: Strategic partnerships and collaborations among industry players are likely to facilitate market expansion and enhance global reach.

Conclusion

In conclusion, the metal stamping market is set for transformative growth over the next decade, fueled by advancements in technology, increased demand from various industries, and emerging trends focused on sustainability and efficiency. By addressing the challenges and capitalizing on opportunities, industry players can position themselves for success in the dynamic global market.

As we look toward 2032, companies that embrace innovative practices and adapt to changing consumer demands will be best positioned to thrive in the evolving metal stamping landscape. Stay tuned for further updates and insights as this market continues to unfold.

The global metal stamping market is poised for significant growth over the next decade, driven by key industry dynamics and emerging trends. As manufacturers and consumers increasingly demand high-quality and durable metal components, the market is undergoing a transformation that promises both challenges and opportunities. This article will explore the major trends shaping the metal stamping industry and provide a comprehensive growth forecast from 2025 to 2032.

The global metal stamping market is poised for significant growth over the next decade, driven by key industry dynamics and emerging trends. As manufacturers and consumers increasingly demand high-quality and durable metal components, the market is undergoing a transformation that promises both challenges and opportunities. This article will explore the major trends shaping the metal stamping industry and provide a comprehensive growth forecast from 2025 to 2032.