Contract manufacturing allows companies to produce high-quality goods without having to invest in their own facilities and equipment. This can save them money and allow them to expand into new markets.

Contract manufacturers can provide a wide range of services, including prototyping, design, and production test runs. They can also help find the best sources for materials and components.

What Are the Benefits of Contract Manufacturing?

The benefits of contract manufacturing in international business include cost savings and access to new markets. Contract manufacturers provide companies with the resources they need to produce their products without having to invest in their own production facilities and employees. This allows businesses to focus on product development and marketing, which can help them grow their customer base and increase profits.

Local firms that manufacture goods under contract for multinational enterprises are often required to adhere to specific production design and quality standards. This can result in a loss of control for foreign enterprises, especially when the local manufacturers have their own product lines.

Another benefit of contract manufacturing is that it can lead to economies of scale. When a contract manufacturer produces more goods, they will have lower per-unit costs for raw materials and labor. This can lead to significant cost savings for the contract manufacturer, which they can pass on to their clients.

It is important for companies to thoroughly vet any potential contract manufacturers. A reputable contract manufacturer will be able to meet delivery deadlines and provide high-quality products. It is also important for a contract manufacturer to have the appropriate expertise and experience in the industry. This is particularly true for highly regulated industries or products that require specialized manufacturing processes. For example, a contract manufacturer that specializes in medical or automotive equipment should have the necessary training and quality assurance processes to ensure that their work meets the relevant regulations.

What Are the Challenges of Contract Manufacturing?

As a growing number of companies outsource their manufacturing to contract producers, it becomes increasingly critical for businesses to understand the benefits and challenges of this type of business practice. For example, it can be difficult to control quality when working with a contract manufacturer located in another country. Additionally, companies may experience delays in production when a contract manufacturer is overwhelmed with orders.

To minimize these risks, it is important for companies to thoroughly vet potential contract manufacturers before signing a contract with them. This includes interviewing contractors and verifying their references. Additionally, it is crucial for companies to understand the cultural differences that can sometimes exist when working with contract manufacturers from different countries.

Despite these challenges, contract manufacturing can be a valuable tool for international businesses. It allows companies to increase their output and access new markets without having to invest the time and money necessary to develop a product from scratch. It also provides flexibility for companies when it comes to product design and customization, which is becoming more popular with consumers.

In addition, contract manufacturing can help companies save on costs by taking advantage of economies of scale. By producing goods in large quantities, contract manufacturers can obtain lower prices on raw materials than individual companies could by purchasing them themselves. Lastly, contract manufacturing can help companies avoid the high upfront costs associated with purchasing their own equipment and hiring in-house staff.

What Are the Solutions to the Challenges of Contract Manufacturing?

In the manufacturing industry, contracting has become a common solution for companies that do not have the resources or capabilities to produce their products in-house. By outsourcing this function to a contracted independent company, a corporation can save resources, boost earnings, and enhance benefits without increasing fixed costs such as equipment and labor. Typically, the contract manufacturer will be responsible for creating one specific component that will be included in the final product development process. Other contractual businesses will then assemble the components into the final product to complete the production.

Choosing the right contract manufacturer is essential for successful outsourcing. A contract manufacturer should be able to meet or exceed the company’s expectations and have a strong track record of quality control. Additionally, a contract manufacturer should be able to communicate effectively with the company. This will ensure that all issues are addressed promptly and efficiently.

A good contract manufacturer will also adhere to all necessary regulatory requirements. This is especially important if the contract manufacturer is producing pharmaceuticals or electronics products which have stringent compliance standards.

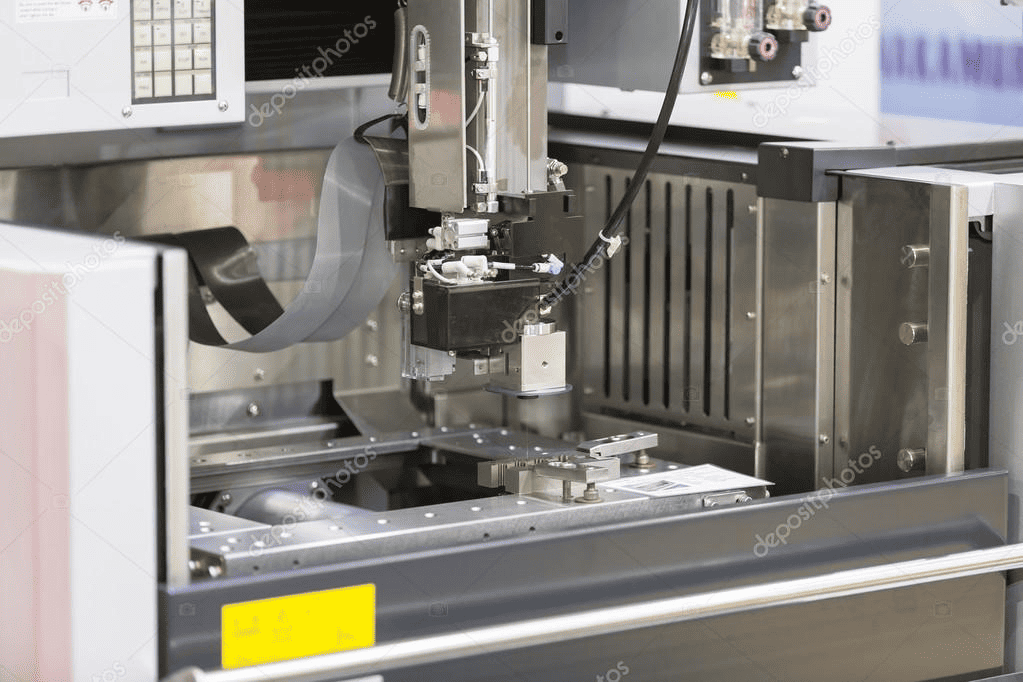

Lastly, a contract manufacturer should have access to a state-of-the-art design and modeling system. This will allow them to create prototypes of products quickly and accurately. This will save time and money in the long run because it will prevent costly mistakes from being made during the production process.

What Are the Benefits of Contract Manufacturing in International Business?

Contract manufacturing is beneficial to international businesses for many reasons. For one, it saves companies the cost of purchasing and maintaining equipment. It also allows businesses to focus on their core products and services. In addition, it gives businesses access to specialized capabilities that may not be available in their home country. Finally, contract manufacturing is a great option for small businesses and startups that lack the resources to produce their own products.

Contract manufacturers benefit from economies of scale, which means that as they service more customers, their costs per unit decrease. This enables them to offer competitive pricing on their products. Additionally, contract manufacturers can often reduce the cost of acquiring raw materials by buying in bulk.

Depending on the type of product, contract manufacturing can help to improve its quality. This is especially important for new and innovative products that need to be perfected before they can be mass-produced. Contract manufacturers can also use their experience and knowledge to spot potential risks or flaws in a product’s design. This can help to prevent costly mistakes that could be fatal to the company’s reputation.

When choosing a contract manufacturer, it is important to take the time to interview and verify references. This will ensure that the contract manufacturer is a good fit for your company. It is also a good idea to perform a cost-benefit analysis on each candidate to determine which would be the best value for your money.